2024-09-29

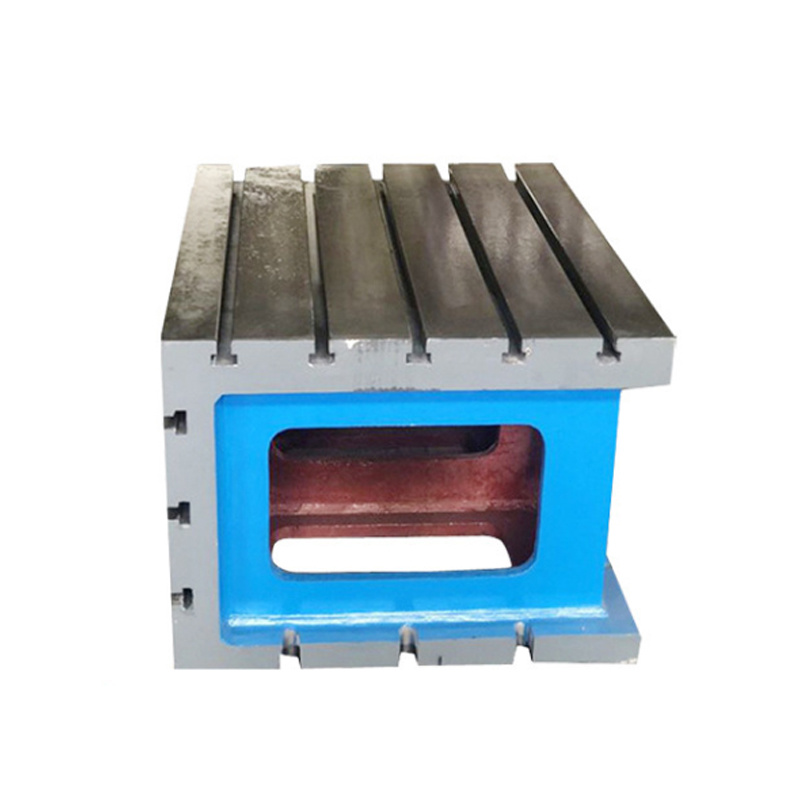

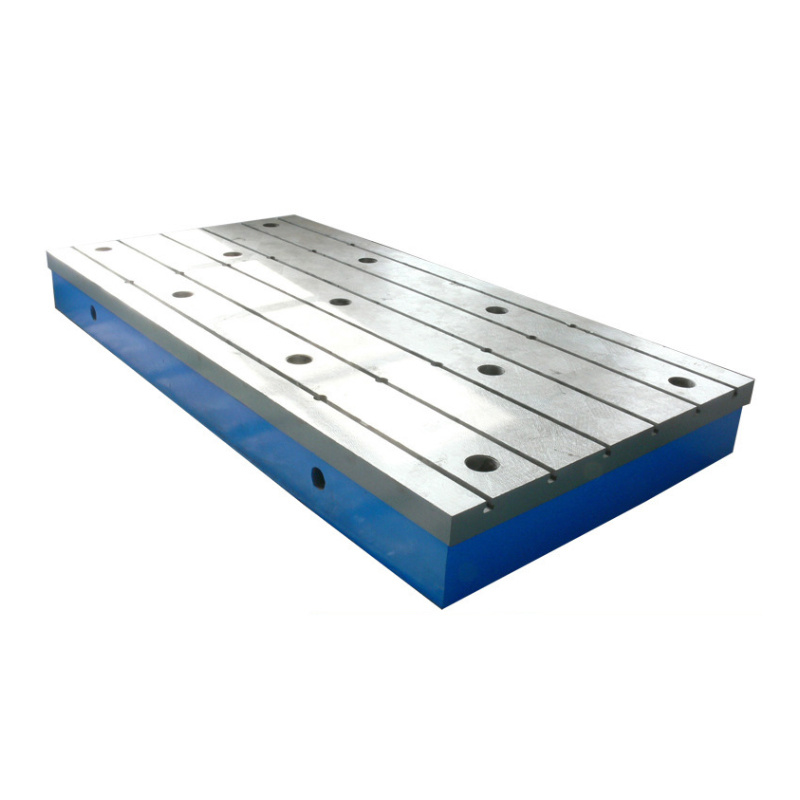

Advantages and characteristics of cast iron platform

After strict precision control and testing, to ensure that the parameters of the platform meet the standard requirements.

2024-09-29

Types and Uses of Cast Iron Platforms

Inspection platform: It is mainly used to test the benchmark of workpiece error.

2024-09-29

How to distinguish the quality of cast iron welding platform

How to distinguish the quality of cast iron welding platform can be divided into several aspects to identify .

2024-08-12

Cast iron square box maintenance and maintenance

Check the working face of the square box regularly for damage or wear, and repair or replace it in time. Avoid impact or heavy pressure on the box to avoid damage to its accuracy and stability. When cleaning the box, use a soft cloth and special detergent, and avoid using corrosive solvents.

2024-08-12

Technical requirements for cast iron square boxes

Working face requirements: no rust, scratches, cracks, dents and other defects that affect measurement performance. Accuracy requirements: For the scraped box, in addition to the flatness verification, it is also necessary to use the coloring method to verify the contact spots. In any square with a side length of 25mm, the number of spots needs to meet the corresponding level requirements (such as not less than 25 points for level 1 and level 2, and not less than 20 points for level

2024-08-12

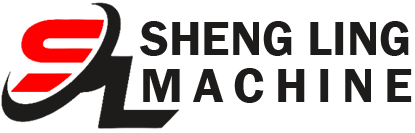

Application field of 3D flexible welding platform

3D flexible welding platform is widely used in many industries because of its high flexibility, intelligence, high efficiency and other advantages. It mainly includes: Automotive industry: can quickly adapt to the diverse needs of automobile production, improve production efficiency and quality. Machinery manufacturing industry: It can complete the welding of various shapes and materials, especially suitable for the welding of mechanical parts that need to be mass-produced.

2024-08-12

The working principle of 3D flexible welding platform

The working principle of the 3D flexible welding platform is relatively simple, but the application is extremely wide. The platform fixes the workpiece to be welded in a predetermined position by precise positioning modules and fixtures, and welds the workpiece by welding equipment. During the welding process, the position and Angle of the welding platform can be adjusted as needed to ensure the accuracy and welding quality of the welding points.

2024-08-12

Application field of cast iron platform

Cast iron platform has a wide range of applications in many fields, including machinery manufacturing, chemical, hardware, aerospace, petroleum, automobile manufacturing, instrument manufacturing and so on. Specific application scenarios include: Inspection of workpiece error: as a benchmark for inspection of workpiece error, to ensure the quality of the workpiece before leaving the factory.

2024-08-12

Characteristics and advantages of cast iron platform

High wear resistance: The cast iron material has excellent wear resistance, can withstand heavy pressure and friction for a long time, and is not easily damaged. Deformation resistance: When the cast iron platform is subjected to external force, it can maintain good shape stability and will not easily deform.

Contact Us

Email:

15720371695@163.com

Tel/Whatsapp:

+86-15720371695

Address:

156 Beituan Village, Jiaohe Town, Botou City, Cangzhou City, Hebei Province, China